- +1-315-215-1633

- sales@thebrainyinsights.com

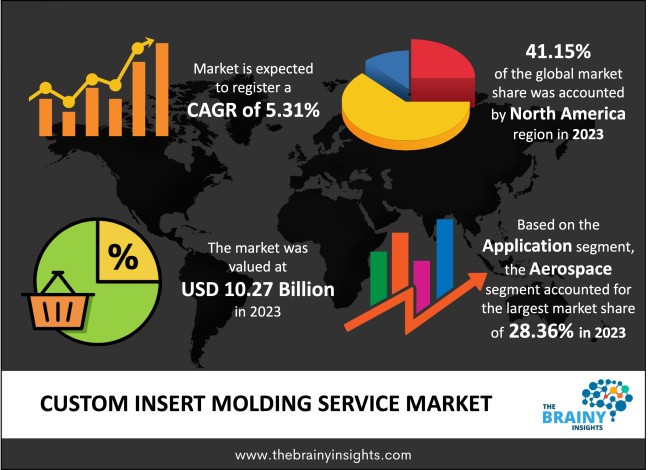

The global Custom Insert Molding Service market generated USD 10.27 Billion revenue in 2023 and is projected to grow at a CAGR of 5.31% from 2024 to 2033. The market is expected to reach USD 17.23 Billion by 2033. This growth of the custom insert molding service market is attributed to a number of factors, among them the global demand for lightweight and durable parts, miniaturization of parts, and integration of parts. Also, in recent years, advances in fabric innovation and reinforced processes have been helpful in the development of better and more specified parts, which has played a massive role in the market’s advancement.

Custom insert molding service is a unique manufacturing process focusing on injecting molten material, preferably in the form of a plastic, into a mold with inserts or other components already in place. These are metal or plastic and are incorporated within the mold to create an integral part of the molded component piece. This process also allows creating elaborate part forms with unique functions and intricately tailored architectures. Insert moldings allow for combining several parts of the final product into one with the help of simultaneous injection molding; it helps reduce the number of steps in production, thus increasing the reliability of the final product and its lifetime. It provides flexible design, enabling the fabrication of both planes or more complicated structures. In summary, this custom inserts molding service is highly advantageous and comparatively inexpensive for manufacturing diverse and superior inserts for numerous industries and uses.

Get an overview of this study by requesting a free sample

Increasing Demand for Customized Products — Consumers are rapidly paying more attention to various products' needs, leading to a higher demand for segmented products throughout various sectors. A specific trend that we observe here is that the necessity for custom insert molding services increases since it allows manufacturers to combine various materials and components in line with their needs.

New Technologies in Manufacturing — Modern technologies, such as automation, three-dimensional printing, and robotics, continuously improve insert molding. These technological improvements can increase the accuracy and speed of manufacturing while also improving the design of parts, which drives the market further.

Growth in the Automotive Industry — Custom insert molding has become considerably popular in the automotive sector, where it is used to create elements such as the dashboard, door panels, and interior trim. Like other sectors, the automotive sector is engulfed by new ideas and growth, as is the requirement for custom insert molding services.

High Initial Investment Costs — Custom insert molding involves high equipment, tools, and skilled labour costs at the beginning of the molding process. Such high costs, which are incurred before production, can threaten small manufacturers or firms with inadequate financial capability.

Complex Design Requirements — Design freedom is a major advantage of custom insert molding. However, this comes with design constraints, especially regarding tooling complexity and manufacturing. Companies are likely to require some assistance in attaining dimensional accuracy, especially in complex product designs with geometric detail or tolerance requirements.

Increasing Demand for Lightweight Components — With emerging concerns of environmental conservation ranging from accountable resource use to fuel efficiency, the requirement for lightweight products and parts in the market sectors of automobiles, aerospace, and electronics is extending. Custom insert molding, where a material with a different characteristic is inserted into another material, and the two are molded together, offers the possibility of producing light but strong articles, and this is an area where service providers may be able to compete.

Expansion in Medical Device Manufacturing — The health sector offers immense growth potential in the healthcare industry, and custom insert molding services are especially relevant in medical devices and equipment. Increasing demand for healthcare services can be attributed to improved medical technology and an ageing population; therefore, an unmet need exists for premium product portfolios that meet the performance, quality, and outcome requirements needed in today's healthcare market.

Material Compatibility Issues — Certain materials are incompatible with custom insert molding, and problems might occur when using one material to combine with another or incorporate inserts with dissimilar properties. This aspect becomes more significantly challenging concerning adhesion, compatibility, and the structural integrity of materials where different materials are utilized or where other unconventional insert materials are to be used.

Tooling and Equipment Investment — Custom insert molding involves specialty tooling, molds, and specialized equipment that depend on the design of the particular part. An obvious disadvantage of investing in tools is that tooling modified to meet the requirements of a new product or the specifications of a particular client can be very costly, hence a deterrent to most small firms or new entrants to the market.

The regions analyzed for the market include North America, Europe, South America, Asia Pacific, the Middle East, and Africa. North America emerged as the most prominent global Custom Insert Molding Service market, with a 41.15% market revenue share in 2023.

North America has advanced and efficient manufacturing structures that will allow jet aircraft manufacturing with modern facilities and tools. The region has key players focusing on insert molding, with most manufacturers having state-of-the-art technology capable of addressing all the needs of their clients. Moreover, the level of adoption of custom insert molding among North American companies remains high due to technological advancements. They remain committed to sustaining research and development to identify and increase the efficiency of the operations to improve the value and recognize and fulfil new and advanced customer needs. Further, the automotive and aerospace industries, the key end users of custom insert molding services, have a notable market share in North America. The automotive production industry, especially in the region, is, in particular, a major consumer of custom insert molding since car makers demand accurate and highly durable components that are used for manufacturing car shells, interior, exterior, and drivetrain systems. Notably, healthcare is well-developed in North America and relies more on custom insert molding to produce medical equipment, operation tools, and disposable items. The healthcare sector in the region requires parts that are high quality and precision-engineered and mandated by regulations to meet the needs of custom insert molding. In addition, North America supports a technological incubation environment with a strong link between industries, universities, and research institutions. This initiative fosters teamwork and enhances the manufacturing of new technologies, materials, and processes in the custom insert molding business, thus helping companies remain relevant and deliver value to stakeholders.

North America Region Custom Insert Molding Service Market Share in 2023 - 41.15%

www.thebrainyinsights.com

Check the geographical analysis of this market by requesting a free sample

The type segment is divided into batch production and prototype making. The prototype making segment dominated the market with a share of around 62.81% in 2023. Creating prototypes is a way to ensure that the idea is correct before manufacturing large quantities of goods in the marketplace and reduces the likelihood of having to correct previous mistakes or not meeting the customer's needs. Thus, when developing models through customized insert molding, firms are well-positioned to evaluate the parts' performance, form and appearance, changes that would be relatively inexpensive in terms of time or resources due to the earlier stages of part development. Another advantage of custom insert molding for prototypes is the reduced time in the development cycle because companies can build prototypes and modify the designs in a shorter period. Soft tooling, a subset of SED, and 3D printing technologies enable the generation of the first articles more quickly than conventional methods in one or two months, giving designers limited time to assess their creation. Furthermore, this works when using the custom insert molding method since it effectively creates cheaper prototypes in a product development cycle. Rather than putting much money into tools and production equipment that can sometimes take several months to arrive, the required tools, including prototype tools, can be bought at a relatively low cost or built up using additive manufacturing technology. Such an approach helps avoid additional expenses on more extensive changes to the design and minimal chances of having to undergo a revised production process when in mass production.

The application segment is classified into aerospace, automobile, medical, consumer products and others. The aerospace segment dominated the market with a share of around 28.36% in 2023. Aerospace structures, interiors, and systems parts must be built to the highest structural integrity and integration standards. From the aerospace business standpoint, custom insert molding allows for combining requirements for various materials and components and their functions into a single unit, which is manufactured in a single process and conforms with high performance and quality levels. Moreover, it opens the opportunities to create the product with the help of custom insert molding; thus, aerospace manufacturers can provide a lighter, more efficient and enhanced part. When it comes to producing aircraft parts, lightweight aircraft with high strength-to-weight ratios need to be achieved through materials with high strength-to-weight ratios and structural inserts to ensure the durability and reliability of the aircraft and overall efficiency and performance. Furthermore, imagination and design organizations that focus on aerospace utilize restricted spaces and have to consider complexity, which adds performance constraints due to the confined dimensions. Users, therefore, use the custom insert molding technique to produce small-sized, integrated, and multi-function components, which not only helps decrease the number of assembly sub-processes but also increases the density of part usage on aircraft interiors and systems.

| Attribute | Description |

|---|---|

| Market Size | Revenue (USD Billion) |

| Market size value in 2023 | USD 10.27 Billion |

| Market size value in 2033 | USD 17.23 Billion |

| CAGR (2024 to 2033) | 5.31% |

| Historical data | 2020-2022 |

| Base Year | 2023 |

| Forecast | 2024-2033 |

| Region | The regions analyzed for the market are Asia Pacific, Europe, South America, North America, and Middle East & Africa. Furthermore, the regions are further analyzed at the country level. |

| Segments | Type and Application |

As per The Brainy Insights, the size of the custom insert molding service market was valued at USD 10.27 billion in 2023 to USD 17.23 billion by 2033.

The global custom insert molding service market is growing at a CAGR of 5.31% during the forecast period 2024-2033.

North America became the largest market for custom insert molding service.

Increasing demand for customized products and advancements in manufacturing technologies drive the market's growth.

1. Introduction

1.1. Objectives of the Study

1.2. Market Definition

1.3. Research Scope

1.4. Currency

1.5. Key Target Audience

2. Research Methodology and Assumptions

3. Executive Summary

4. Premium Insights

4.1. Porter’s Five Forces Analysis

4.2. Value Chain Analysis

4.3. Top Investment Pockets

4.3.1. Market Attractiveness Analysis By Type

4.3.2. Market Attractiveness Analysis By Application

4.3.3. Market Attractiveness Analysis By Region

4.4. Industry Trends

5. Market Dynamics

5.1. Market Evaluation

5.2. Drivers

5.2.1. Increasing Demand for Customized Products

5.2.2. Advancements in Manufacturing Technologies

5.3. Restraints

5.3.1. Budget Constraints

5.4. Opportunities

5.4.1. Increasing Demand for Lightweight Components

5.5. Challenges

5.5.1. Material Compatibility Issues

6. Global Custom Insert Molding Service Market Analysis and Forecast, By Type

6.1. Segment Overview

6.2. Batch Production

6.3. Prototype Making

7. Global Custom Insert Molding Service Market Analysis and Forecast, By Application

7.1. Segment Overview

7.2. Aerospace

7.3. Automobile

7.4. Medical

7.5. Consumer Products

7.6. Others

8. Global Custom Insert Molding Service Market Analysis and Forecast, By Regional Analysis

8.1. Segment Overview

8.2. North America

8.2.1. U.S.

8.2.2. Canada

8.2.3. Mexico

8.3. Europe

8.3.1. Germany

8.3.2. France

8.3.3. U.K.

8.3.4. Italy

8.3.5. Spain

8.4. Asia-Pacific

8.4.1. Japan

8.4.2. China

8.4.3. India

8.5. South America

8.5.1. Brazil

8.6. Middle East and Africa

8.6.1. UAE

8.6.2. South Africa

9. Global Custom Insert Molding Service Market-Competitive Landscape

9.1. Overview

9.2. Market Share of Key Players in the Custom Insert Molding Service Market

9.2.1. Global Company Market Share

9.2.2. North America Company Market Share

9.2.3. Europe Company Market Share

9.2.4. APAC Company Market Share

9.3. Competitive Situations and Trends

9.3.1. Product Launches and Developments

9.3.2. Partnerships, Collaborations, and Agreements

9.3.3. Mergers & Acquisitions

9.3.4. Expansions

10. Company Profiles

10.1. Aline Components

10.1.1. Business Overview

10.1.2. Company Snapshot

10.1.3. Company Market Share Analysis

10.1.4. Company Product Portfolio

10.1.5. Recent Developments

10.1.6. SWOT Analysis

10.2. Aspec

10.2.1. Business Overview

10.2.2. Company Snapshot

10.2.3. Company Market Share Analysis

10.2.4. Company Product Portfolio

10.2.5. Recent Developments

10.2.6. SWOT Analysis

10.3. Crescent Industries

10.3.1. Business Overview

10.3.2. Company Snapshot

10.3.3. Company Market Share Analysis

10.3.4. Company Product Portfolio

10.3.5. Recent Developments

10.3.6. SWOT Analysis

10.4. Eigen

10.4.1. Business Overview

10.4.2. Company Snapshot

10.4.3. Company Market Share Analysis

10.4.4. Company Product Portfolio

10.4.5. Recent Developments

10.4.6. SWOT Analysis

10.5. EVCO Plastics

10.5.1. Business Overview

10.5.2. Company Snapshot

10.5.3. Company Market Share Analysis

10.5.4. Company Product Portfolio

10.5.5. Recent Developments

10.5.6. SWOT Analysis

10.6. Fabrik Molded Plastics, Inc.

10.6.1. Business Overview

10.6.2. Company Snapshot

10.6.3. Company Market Share Analysis

10.6.4. Company Product Portfolio

10.6.5. Recent Developments

10.6.6. SWOT Analysis

10.7. Ferriot Inc.

10.7.1. Business Overview

10.7.2. Company Snapshot

10.7.3. Company Market Share Analysis

10.7.4. Company Product Portfolio

10.7.5. Recent Developments

10.7.6. SWOT Analysis

10.8. FacFox

10.8.1. Business Overview

10.8.2. Company Snapshot

10.8.3. Company Market Share Analysis

10.8.4. Company Product Portfolio

10.8.5. Recent Developments

10.8.6. SWOT Analysis

10.9. IN3DTEC

10.9.1. Business Overview

10.9.2. Company Snapshot

10.9.3. Company Market Share Analysis

10.9.4. Company Product Portfolio

10.9.5. Recent Developments

10.9.6. SWOT Analysis

10.10. Kaysun Corporation

10.10.1. Business Overview

10.10.2. Company Snapshot

10.10.3. Company Market Share Analysis

10.10.4. Company Product Portfolio

10.10.5. Recent Developments

10.10.6. SWOT Analysis

10.11. Lomont Molding

10.11.1. Business Overview

10.11.2. Company Snapshot

10.11.3. Company Market Share Analysis

10.11.4. Company Product Portfolio

10.11.5. Recent Developments

10.11.6. SWOT Analysis

10.12. Moldtronics

10.12.1. Business Overview

10.12.2. Company Snapshot

10.12.3. Company Market Share Analysis

10.12.4. Company Product Portfolio

10.12.5. Recent Developments

10.12.6. SWOT Analysis

10.13. Natech Plastics

10.13.1. Business Overview

10.13.2. Company Snapshot

10.13.3. Company Market Share Analysis

10.13.4. Company Product Portfolio

10.13.5. Recent Developments

10.13.6. SWOT Analysis

10.14. Proto Labs, Inc.

10.14.1. Business Overview

10.14.2. Company Snapshot

10.14.3. Company Market Share Analysis

10.14.4. Company Product Portfolio

10.14.5. Recent Developments

10.14.6. SWOT Analysis

10.15. Plastic Molding Technology, Inc.

10.15.1. Business Overview

10.15.2. Company Snapshot

10.15.3. Company Market Share Analysis

10.15.4. Company Product Portfolio

10.15.5. Recent Developments

10.15.6. SWOT Analysis

10.16. PCBWay

10.16.1. Business Overview

10.16.2. Company Snapshot

10.16.3. Company Market Share Analysis

10.16.4. Company Product Portfolio

10.16.5. Recent Developments

10.16.6. SWOT Analysis

10.17. RapidDirect

10.17.1. Business Overview

10.17.2. Company Snapshot

10.17.3. Company Market Share Analysis

10.17.4. Company Product Portfolio

10.17.5. Recent Developments

10.17.6. SWOT Analysis

10.18. RJC Mold

10.18.1. Business Overview

10.18.2. Company Snapshot

10.18.3. Company Market Share Analysis

10.18.4. Company Product Portfolio

10.18.5. Recent Developments

10.18.6. SWOT Analysis

10.19. RSP, Inc.

10.19.1. Business Overview

10.19.2. Company Snapshot

10.19.3. Company Market Share Analysis

10.19.4. Company Product Portfolio

10.19.5. Recent Developments

10.19.6. SWOT Analysis

10.20. Springboard

10.20.1. Business Overview

10.20.2. Company Snapshot

10.20.3. Company Market Share Analysis

10.20.4. Company Product Portfolio

10.20.5. Recent Developments

10.20.6. SWOT Analysis

10.21. SEA-LECT Plastics Corporation

10.21.1. Business Overview

10.21.2. Company Snapshot

10.21.3. Company Market Share Analysis

10.21.4. Company Product Portfolio

10.21.5. Recent Developments

10.21.6. SWOT Analysis

10.22. TechNH, Inc.

10.22.1. Business Overview

10.22.2. Company Snapshot

10.22.3. Company Market Share Analysis

10.22.4. Company Product Portfolio

10.22.5. Recent Developments

10.22.6. SWOT Analysis

10.23. Veejay Plastic

10.23.1. Business Overview

10.23.2. Company Snapshot

10.23.3. Company Market Share Analysis

10.23.4. Company Product Portfolio

10.23.5. Recent Developments

10.23.6. SWOT Analysis

10.24. Xcentric Mold & Engineering

10.24.1. Business Overview

10.24.2. Company Snapshot

10.24.3. Company Market Share Analysis

10.24.4. Company Product Portfolio

10.24.5. Recent Developments

10.24.6. SWOT Analysis

10.25. Xometry

10.25.1. Business Overview

10.25.2. Company Snapshot

10.25.3. Company Market Share Analysis

10.25.4. Company Product Portfolio

10.25.5. Recent Developments

10.25.6. SWOT Analysis

List of Table

1. Global Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

2. Global Batch Production, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

3. Global Prototype Making, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

4. Global Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

5. Global Aerospace, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

6. Global Automobile, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

7. Global Medical, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

8. Global Consumer Products, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

9. Global Others, Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

10. Global Custom Insert Molding Service Market, By Region, 2020-2033 (USD Billion)

11. North America Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

12. North America Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

13. U.S. Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

14. U.S. Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

15. Canada Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

16. Canada Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

17. Mexico Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

18. Mexico Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

19. Europe Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

20. Europe Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

21. Germany Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

22. Germany Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

23. France Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

24. France Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

25. U.K. Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

26. U.K. Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

27. Italy Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

28. Italy Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

29. Spain Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

30. Spain Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

31. Asia Pacific Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

32. Asia Pacific Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

33. Japan Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

34. Japan Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

35. China Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

36. China Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

37. India Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

38. India Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

39. South America Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

40. South America Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

41. Brazil Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

42. Brazil Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

43. Middle East and Africa Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

44. Middle East and Africa Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

45. UAE Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

46. UAE Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

47. South Africa Custom Insert Molding Service Market, By Type, 2020-2033 (USD Billion)

48. South Africa Custom Insert Molding Service Market, By Application, 2020-2033 (USD Billion)

List of Figures

1. Global Custom Insert Molding Service Market Segmentation

2. Custom Insert Molding Service Market: Research Methodology

3. Market Size Estimation Methodology: Bottom-Up Approach

4. Market Size Estimation Methodology: Top-Down Approach

5. Data Triangulation

6. Porter’s Five Forces Analysis

7. Value Chain Analysis

8. Global Custom Insert Molding Service Market Attractiveness Analysis By Type

9. Global Custom Insert Molding Service Market Attractiveness Analysis By Application

10. Global Custom Insert Molding Service Market Attractiveness Analysis By Region

11. Global Custom Insert Molding Service Market: Dynamics

12. Global Custom Insert Molding Service Market Share By Type (2024 & 2033)

13. Global Custom Insert Molding Service Market Share By Application (2024 & 2033)

14. Global Custom Insert Molding Service Market Share By Regions (2024 & 2033)

15. Global Custom Insert Molding Service Market Share by Company (2023)

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. The Brainy Insights has segmented the global Custom Insert Molding Service market based on below-mentioned segments:

Global Custom Insert Molding Service Market by Type:

Global Custom Insert Molding Service Market by Application:

Global Custom Insert Molding Service Market by Region:

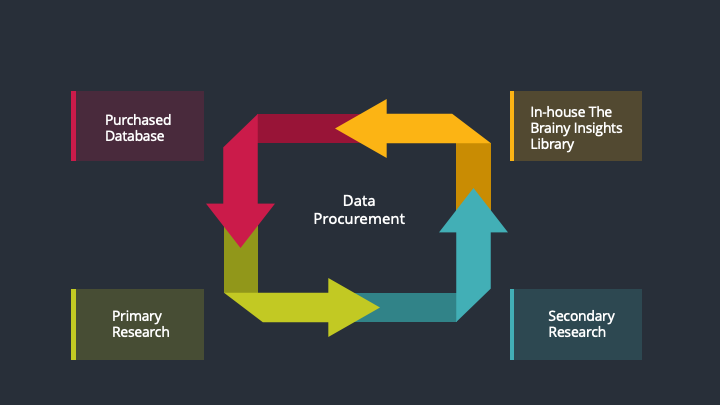

Research has its special purpose to undertake marketing efficiently. In this competitive scenario, businesses need information across all industry verticals; the information about customer wants, market demand, competition, industry trends, distribution channels etc. This information needs to be updated regularly because businesses operate in a dynamic environment. Our organization, The Brainy Insights incorporates scientific and systematic research procedures in order to get proper market insights and industry analysis for overall business success. The analysis consists of studying the market from a miniscule level wherein we implement statistical tools which helps us in examining the data with accuracy and precision.

Our research reports feature both; quantitative and qualitative aspects for any market. Qualitative information for any market research process are fundamental because they reveal the customer needs and wants, usage and consumption for any product/service related to a specific industry. This in turn aids the marketers/investors in knowing certain perceptions of the customers. Qualitative research can enlighten about the different product concepts and designs along with unique service offering that in turn, helps define marketing problems and generate opportunities. On the other hand, quantitative research engages with the data collection process through interviews, e-mail interactions, surveys and pilot studies. Quantitative aspects for the market research are useful to validate the hypotheses generated during qualitative research method, explore empirical patterns in the data with the help of statistical tools, and finally make the market estimations.

The Brainy Insights offers comprehensive research and analysis, based on a wide assortment of factual insights gained through interviews with CXOs and global experts and secondary data from reliable sources. Our analysts and industry specialist assume vital roles in building up statistical tools and analysis models, which are used to analyse the data and arrive at accurate insights with exceedingly informative research discoveries. The data provided by our organization have proven precious to a diverse range of companies, facilitating them to address issues such as determining which products/services are the most appealing, whether or not customers use the product in the manner anticipated, the purchasing intentions of the market and many others.

Our research methodology encompasses an idyllic combination of primary and secondary initiatives. Key phases involved in this process are listed below:

The phase involves the gathering and collecting of market data and its related information with the help of different sources & research procedures.

The data procurement stage involves in data gathering and collecting through various data sources.

This stage involves in extensive research. These data sources includes:

Purchased Database: Purchased databases play a crucial role in estimating the market sizes irrespective of the domain. Our purchased database includes:

Primary Research: The Brainy Insights interacts with leading companies and experts of the concerned domain to develop the analyst team’s market understanding and expertise. It improves and substantiates every single data presented in the market reports. Primary research mainly involves in telephonic interviews, E-mail interactions and face-to-face interviews with the raw material providers, manufacturers/producers, distributors, & independent consultants. The interviews that we conduct provides valuable data on market size and industry growth trends prevailing in the market. Our organization also conducts surveys with the various industry experts in order to gain overall insights of the industry/market. For instance, in healthcare industry we conduct surveys with the pharmacists, doctors, surgeons and nurses in order to gain insights and key information of a medical product/device/equipment which the customers are going to usage. Surveys are conducted in the form of questionnaire designed by our own analyst team. Surveys plays an important role in primary research because surveys helps us to identify the key target audiences of the market. Additionally, surveys helps to identify the key target audience engaged with the market. Our survey team conducts the survey by targeting the key audience, thus gaining insights from them. Based on the perspectives of the customers, this information is utilized to formulate market strategies. Moreover, market surveys helps us to understand the current competitive situation of the industry. To be precise, our survey process typically involve with the 360 analysis of the market. This analytical process begins by identifying the prospective customers for a product or service related to the market/industry to obtain data on how a product/service could fit into customers’ lives.

Secondary Research: The secondary data sources includes information published by the on-profit organizations such as World bank, WHO, company fillings, investor presentations, annual reports, national government documents, statistical databases, blogs, articles, white papers and others. From the annual report, we analyse a company’s revenue to understand the key segment and market share of that organization in a particular region. We analyse the company websites and adopt the product mapping technique which is important for deriving the segment revenue. In the product mapping method, we select and categorize the products offered by the companies catering to domain specific market, deduce the product revenue for each of the companies so as to get overall estimation of the market size. We also source data and analyses trends based on information received from supply side and demand side intermediaries in the value chain. The supply side denotes the data gathered from supplier, distributor, wholesaler and the demand side illustrates the data gathered from the end customers for respective market domain.

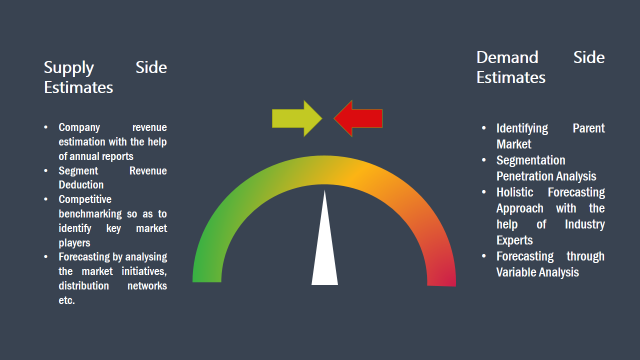

The supply side for a domain specific market is analysed by:

The demand side for the market is estimated through:

In-house Library: Apart from these third-party sources, we have our in-house library of qualitative and quantitative information. Our in-house database includes market data for various industry and domains. These data are updated on regular basis as per the changing market scenario. Our library includes, historic databases, internal audit reports and archives.

Sometimes there are instances where there is no metadata or raw data available for any domain specific market. For those cases, we use our expertise to forecast and estimate the market size in order to generate comprehensive data sets. Our analyst team adopt a robust research technique in order to produce the estimates:

Data Synthesis: This stage involves the analysis & mapping of all the information obtained from the previous step. It also involves in scrutinizing the data for any discrepancy observed while data gathering related to the market. The data is collected with consideration to the heterogeneity of sources. Robust scientific techniques are in place for synthesizing disparate data sets and provide the essential contextual information that can orient market strategies. The Brainy Insights has extensive experience in data synthesis where the data passes through various stages:

Market Deduction & Formulation: The final stage comprises of assigning data points at appropriate market spaces so as to deduce feasible conclusions. Analyst perspective & subject matter expert based holistic form of market sizing coupled with industry analysis also plays a crucial role in this stage.

This stage involves in finalization of the market size and numbers that we have collected from data integration step. With data interpolation, it is made sure that there is no gap in the market data. Successful trend analysis is done by our analysts using extrapolation techniques, which provide the best possible forecasts for the market.

Data Validation & Market Feedback: Validation is the most important step in the process. Validation & re-validation via an intricately designed process helps us finalize data-points to be used for final calculations.

The Brainy Insights interacts with leading companies and experts of the concerned domain to develop the analyst team’s market understanding and expertise. It improves and substantiates every single data presented in the market reports. The data validation interview and discussion panels are typically composed of the most experienced industry members. The participants include, however, are not limited to:

Moreover, we always validate our data and findings through primary respondents from all the major regions we are working on.

Free Customization

Fortune 500 Clients

Free Yearly Update On Purchase Of Multi/Corporate License

Companies Served Till Date